The Joint Combat Aircraft (previously Future Joint Combat Aircraft) was originally intended to replace Sea Harrier in the Fleet Air Arm, and Harriers in the RAF. It selected the Joint Strike Fighter F35 as preferred solution in 2001, but for a long time never never really decided between STOVL and CV variants. The JCA programme has been heavily influenced by events connected to the Joint Harrier Force and, even more, it has been shaped partially by the Future Offensive Air System (Tornado replacement programme targeted at delivering a Deep Penetration Strike aicraft) programme of the RAF.

In particular, JCA has been ultimately shaped by the killing of the FOAS programme, which put the RAF to terms with the truth: JCA would not just replace the Harrier, but the Tornado GR4 as well.

In 2010, as we know, the final (?) choice was the F35C variant. Let's take a better, closer look into this saga.

Joint Combat Aircraft JCA

The "Joint Combat Aircraft" (JCA) project originated as a Sea Harrier replacement "Future Carrier Borne Aircraft" (FCBA) program to provide the fleet with a new fighter and attack aircraft to succeed the Sea Harrier from 2012. The JCA project is obviously closely related to the Future Aircraft Carrier (CVF) project to replace the Invincible Class aircraft carriers.

On 17 January 2001 it was announced that the Joint Strike Fighter has been selected to meet the UK's FCBA requirement. On 26 October 2001 it was announced that Lockheed Martin had won the Prime Contract to develop the Joint Strike Fighter F-35. The F-35B STOVL variant was officially announced as the preferred joice for JCA in September 2002, but in reality the nature of the F35 order has been under a constant review, which ultimately saw the switch to the F35C variant in SDSR 2010.

Since 2001 the MOD regularly stated an intent to buy up to 150 JCA's at a cost of about ₤8 billion, however Lockheed Martin sources reported (in 2006) an expected UK buy of about 138 of the F-35 Lightning II planes, over the period 2011-2027. About 80 of these were to be F-35B short take-off/vertical landing (STOVL) variant, intended to meet the Joint Combat Aircraft requirement as a replacement for the Harrier GR.9 and the already out of service Sea Harrier FA.2 in RAF and RN service. These 80 planes were planned to constitute 4 Squadrons in a Joint Force Lightning, re-equipping the Harrier squadrons (800° and 801° NAS, 1° and 4° RAF). The remainder of the planned UK buy was reportedly re-assigned in 2006 to form the manned element of a successor deep strike capability to replace the RAF's Tornado GR.4, an interesting consequence of the death (in 2005) of the FOAS programme which should have given the RAF a dedicate replacement for Tornado on top of the JCA planes.

In 2000, Joint Force Harrier was created, with the RAF lining 20(R) Squadron as OCU, 1° and IV° Squadrons frontline, with Harrier GR7 ground-attack (later upgraded to GR9 standard). The Fleet Air Arm contributed 800, 801 and 899 (the Sea Harrier OCU) squadrons.

In January 2002 it was announced that the MOD wasn't able to fund the upgrades necessary to keep the Sea Harrier FA.2 fighter in service to 2015 as previously planned, arguing that the F35 was expected (totally unrealistically, but this did not matter to politicians) in service in 2012 and that significant expenditure would be required to upgrade the Sea Harrier fleet for only six years of service. Sea Harrier was retired by 29 March 2006, effectively killing the fixed wing Fleet Air Arm.

One former front-line Sea Harrier Squadron (800 Naval Air Squadron) was re-commissioned 31 March 2006, re-equipped with 9 Harrier GR.7 and GR.9 Harriers made available by the RAF, which had in the meanwhile re-equipped its 3° Squadron on the Eurofighter Typhoon (so, the RAF did not gift anything to anyone, let’s be very clear on this). 800 NAS was the first Royal Navy air squadron falling under RAF Strike Command control. The “generosity” of the RAF had in fact been a way for the Junior Service to gain one more squadron.

800 NAS was to fly from HMS Illustrious (HMS Invincible had left service in 2005, heading into reserve, and HMS Ark Royal had been re-roled as an LPH amphibious ship, situation which was later inversed at the successive refit time (2009) which saw Ark Royal taking on Strike Carrier role after 12 million pounds worth of upgrades, which has maintained up to her early retirement with SDSR2010). The Naval Strike Wing, however, was tasked with Afghanistan deployment, and its Harriers and personnel spent five years in theatre, leaving HMS Illustrious always with empty decks: to keep carrier strike expertise alive as much as possible, the RN had to invite on board of Illustrious US Marine Corps Harriers (July 2007, was a record-breaking exercise with 14 USMC Harriers and over 200 Marines operating on Lusty) and again five Spanish and a few Italian Harriers during training in the Mediterranean. It was only in march 2010 that the Naval Strike Wing finally made it back to sea, deploying on HMS Ark Royal, when (finally) the RAF provided Tornado jets for Afghanistan.

Labour’s SDR had indicated that there would be a combined RN/RAF FCBA buy of up to 150 aircraft - rather than separate buys of 60+90 aircraft to replace the Sea Harrier and Harrier respectively. This latter became a RAF JCA buy of up to 150 aircraft as it was decided that the RAF would actually "own" all the aircraft at a cost of about £7 billion. The Royal Navy barely managed to obtain the promise that two of the four carrier-capable JCA squadrons will be (predominantly) dark-blue manned and operated. Left without Sea Harriers, brought under Strike Command RAF control, the fleet air arm fixed wing capability was effectively killed in 2006.

On 31 March 2010, the Harrier force was reduced by one squadron with the disbandment of No. 20 Squadron RAF, the Harrier Operational Conversion Unit (OCU). No. 4 Squadron also disbanded and reformed as No. 4 (Reserve) Squadron at RAF Wittering, taking over as the OCU. At the same time, Joint Force Harrier was renamed Joint Strike Wing and all remaining Harrier GR7 aircraft were retired, leaving only two frontline squadrons flying Harrier GR9, the 800 NAS and 1° RAF, with IV° RAF serving as OCU. All these squadrons have disbanded after SDSR 2010 with the early retirement of the Harrier, which was to soldier on until 2019.

Another ex-Sea Harrier squadron, 801 NAS was expected to commission in October 2006 but this was foiled by a lack of naval pilots, and the target data was delayed. Instead a Naval Strike Wing was formed in March 2007, which officially comprises of elements of both 800 and 801 Squadrons - although this was still equivalent in strength to just one 9 aircraft squadron, rather than the two originally planned. The Naval Strike Wing reverted to 800 NAS identity in April 2010.

In April 2003 UK press reports said that the JCA order was likely to be cut to 110, and in February 2004 the American magazine Aviation Week suggested that as few as 80-85 JSF's might have been bought by the UK - which might have required a cut in planned force levels, from 12 to 9 airplanes for squadron, as with the Harrier. This was due to the RAF trying to keep the FOAS, Future Offensive Air System, alive and on a parallel track as JCA’s own one. And in fact, in June 2006, after the FOAS was killed in 2005 and the RAF ordered to plan a future fleet of Typhoon and JCA only, official (US) JSF program sources stated that the UK was expected to buying 138 JSF's.

Regardless of the variant chosen, the first two or three UK Joint Strike Fighters were expected to be delivered in 2011/12 for trials purposes. Official entry in to service was originally 2012 but was delayed until 2014 by technical problems. Budget shortfalls resulted in the MOD's Equipment Plan 2007 (EP2007) further delaying the in-service date to 2017 to reduce budgetary pressures. After the SDSR 2010 an IOC with 8 operative planes is likely in 2018, with the first deployment of an operational squadron on CVF expected by 2020. RAF sources also have reported that, due to the budget crisis, only 40 F35C are expected to be acquired by 2020, even if the plan for the long term is to operate “up to 100” JCA planes. An updated MOD-official, government-endorsed figure for the JCA fleet is currently (april 2011) not available, and while the 150 and 138 figures still are reported by LM and other sources, a reduced buy is now certain. Its consistency should be determined by the next Strategic Defence Review in 2015.

The UK has ordered its fleet of 3 F35 test planes, but contract details were worked out by Labour, and the order was made for 3 F35B. Britain is thus now paying £389m to buy 3 F-35B jump jets even though last year’s defence review ruled that the Armed Forces did not need vertical take-off and landing fighters. Negotiations are reportedly ongoing to change at least the third plane from a B to a C variant, but LM is resisting the MOD attempts at renegotiating the contract. Lockheed Martin has not been happy at all of the UK’s change of mind, which has been seen as a hard blow to the trouble-plagued F35B programme. The only comfort is that the F35Bs will still offer valuable indications of performances of the common avionics system, and the roughly 70% commonality between variants should ensure to the UK that plenty of useful tests can be done, despite all. A RN team is also already present on the US Navy Air Base Patuxent River, near Washington, where the first F35C is being evaluated and tested. The CF-1 F35C has been recently hooked to the catapult used on Nimitz carriers, and live launches from an aircraft carrier of the US Navy are planned for 2013.

The F35C

US Navy carrier operations needs are the source of the differences between the F-35C and the other JSF variants. The aircraft has larger wing and tail control surfaces to better manage low-speed carrier approaches. The F-35C has an increased-capacity structure for absorbing catapult launches and arrested landings, folding wingtips, and greater internal fuel capacity thanks to the bigger space available inside the airframe. The F-35C carrier-based (CV) variant will complement the US Navy's F/A-18E/Fs and replace F-14s and earlier model F/A-18s in US Navy and Marines service, while it is now destined to replace Harrier GR9, Sea Harrier and Tornado GR4 in the UK. Like the Marine variant, the Navy variant carries a House and Drogue refueling probe on the right side of the forward fuselage, perfectly compatible with standard equipment and procedures in the Royal Air Force, while the F35A, reflecting the operational doctrine of the USAF, has no refueling probe but a receptacle for boom AAR refueling. The aircraft carries an internal laser designator and will employ a gunpod fitted to the dedicate centerline pylon under the fuselage. Originally, all F35 variants were expected to employ a variant of the Mauser BK-27 gun used, notably, by Typhoon and Tornado, but this proved impossible, and only the F35A features an internal gun, while the F35B and C will use an external pod with the purposefully-designed GAU-22A gatling gun, a four-barrel variant of the GAU-12 Equalizer 25 mm gun. Cockpit layout, countermeasures, radar and other features are common for all the variants, while the internal weapons load of the F35B is limited to 1000 lbs bombs because the bays are shorter by 14 inches. F35C and F35A will both be capable to employ internally-stored 2000lbs-class weaponry.

|

| Folding wingtips compensate the greater wingspan of the F35C variant. |

An integrated airframe design, advanced materials and an asymmetric nozzle maximize the F-35's stealth features. A quick look at the aircraft reveals an adherence to fundamental shaping principles of a stealthy design. The leading and trailing edges of the wing and tail have identical sweep angles (a design technique called planform alignment). The fuselage and canopy have sloping sides. The canopy seam and bay doors are sawtoothed. The vertical tails are canted. The engine face is deeply hidden by a serpentine inlet duct. The inlet itself has no boundary layer diverter channel, the space between the duct and the fuselage, to reflect radar energy. And, of course, weapons can be carried internally. Each internal bay contains two hardpoints onto which a wide variety of bombs and missiles can be attached.

According to November 2005 reports, the US Air Force states that the F-22 has the lowest RCS of any manned aircraft in the USAF inventory, with a frontal RCS of 0.0001~0.0002 m2, marble sized in frontal aspect. According to these reports, the F-35 is said to have an RCS equal to a metal golf ball, about 0.0015m2, which is about 5 to 10 times greater than the minimal frontal RCS of F/A-22. The F-35 has a lower RCS than the F-117 and is comparable to the B-2, which was half that of the older F-117. Other reports claim that the F-35 is said to have an smaller RCS headon than the F-22, but from all other angles the F-35 RCS is greater. By comparison, the RCS of the Mig-29 is about 5m2.

The F-35 RAM is thicker, more durable, less expensive and, being manufactured to tighter tolerances compared to that of the F-22. The tighter tolerances means less radar signal can penetrate openings and reflect back to its source. The newer RAM is more effective against lower frequency radars, and maintenance should cost about a tenth that of the F-22 or B-2. The F35 RAM coating has been performing so well, indeed, that it is being used in upgrades to the F22 Raptor itself.

The F35C, as all JSFs, will employ the AN/APG-81 Multi-Mission Active Electronically Scanned Array (AESA) Radar. The AN/APG-81 is a successor radar to the F-22's AN/APG-77. By August 2007, 8 APG-81s had already been produced and delivered. The first three blocks of radar software had been developed, flight tested, and delivered ahead of schedule by the Northrop Grumman Corporation. Capabilities of the AN/APG-81 include the AN/APG-77's air-to-air modes and add advanced air-to-ground modes including high resolution mapping, multiple ground moving target detection and track, combat identification, electronic warfare, and ultra high bandwidth communications. The AN/APG-81 uses improved technology compared to the F-22's AN/APG-77, but airframe constraints mean that it has fewer T/R modules, limiting it to about two-thirds the range (165 kilometers / 90 nautical miles) of the AN/APG-77.

On 6/22/2010 it was announced that the radar met and exceeded its performance objectives, successfully tracking long-range targets as part of the first mission systems test flights of the F-35 Lightning II BF-4 development aircraft. http://www.irconnect.com/noc/press/pages/news_releases.html?d=194881

In a joint effort with Lockheed Martin Missiles and Fire Control, Northrop Grumman Electronic Systems will provide key electronic sensors for the F-35, which includes spearheading the work on the Electro-Optical Distributed Aperture System (DAS). This system will provide pilots with a unique protective sphere around the aircraft for enhanced situational awareness, missile warning, aircraft warning, day/night pilot vision, and fire control capability. Designated the AN/AAQ-37, and comprising six electro-optical sensors, the full EO DAS will enhance the F-35's survivability and operational effectiveness by warning the pilot of incoming aircraft and missile threats, providing day/night vision at 360 degrees and supporting the navigation function of the F-35's forward-looking infrared sensor.

|

| The DAS system provides unique, 360° spherical coverage to the pilot, allowing him to see even across the airframe. |

Lockheed Martin Missiles and Fire Control and Northrop Grumman Electronic Systems are jointly providing key electronic sensors for the F-35 to include the Electro-Optical Targeting System (EOTS). The internally mounted EOTS will provide extended range detection and precision targeting against ground targets, plus long range detection of air-to-air threats.

The Electro-Optical Targeting System is an high-performance, lightweight, multi-functional system for precision air-to-air and air-to-surface targeting. The low-drag, stealthy EOTS is integrated into the Joint Strike Fighter's fuselage with a durable sapphire window and is linked to the aircraft's integrated central computer through a high-speed fiber-optic interface.

|

| The EOTS seeker is located under the nose of the plane |

The EOTS uses a staring midwave 3rd generation FLIR that provides superior target detection and identification at greatly increased standoff ranges. EOTS also provides high-resolution imagery, automatic tracking, infrared-search-and-track, laser designation and rangefinding, and laser spot tracking. This gives the same capabilities as the Lockheed Martin Sniper XR pod while avoiding making the plane more easily detectable and providing high reliability and efficient two-level maintenance. The F-35's electronic warfare systems are intended to detect hostile aircraft first, which can then be scanned with the electro-optical system and action taken to engage or evade the opponent before the F-35 is detected. The F35 development sensors kit fitted on CATbird avionics testbed has proved capable of detecting and jamming F-22 radars. In a series of tests at Edwards AFB, Calif., in 2009, Lockheed Martin’s CATbird avionics testbed—a Boeing 737 that carries the F-35 Joint Strike Fighter’s entire avionics system—engaged a mixed force of F-22s and Boeing F-15s and was able to locate and jam F-22 radars, according to researchers. Raytheon’s family of X-band airborne AESA radar—in particular, those on upgraded F-15Cs stationed in Okinawa—can detect small, low-signature cruise missiles. This was reported by Aviation Week.

The communications, navigation and identification (CNI) suite is designed by Northrop Grumman and includes the Multifunction Advanced Data Link (MADL). The F-35 will be the first jet fighter that has sensor fusion that combines both radio frequency and IR tracking for continuous target detection and identification in all directions which is shared via MADL to other platforms without compromising low observability. The MADL is a future data waveform to provide secure data-linking technology between stealth aircraft. It is planned that during the upgrade 3.2, the USAF will add this system to the F22. In early 2011, however, this project was deferred. Ultimately, USAF aims to add MADL to all its stealth platforms, including B2 and future UAVs and UCAVs.

Lockheed Martin Missiles and Fire Control is teamed with Northrop Grumman Electronic Systems to produce the JSFTM Electro-Optical Sensor System (EOSS). The EOSS consists of the EOTS, led by Lockheed Martin with BAE SYSTEMS, and the Distributed Aperture System, which provides 360-degree situational awareness, led by Northrop Grumman. A cornerstone of future defense capability for the U.S. and its allies, the EOSS supports situational awareness, target recognition, and precision weapon delivery.

|

| VSI's Helmet Mounted Display System helmet for the F35 pilots |

Unlike the cockpit design of current-generation fighter aircraft, the F-35’s does not include a head-up display. Rather, the information normally visible on such a display is instead projected on the pilot’s helmet visor. Vision Systems International, LLC (VSI) is developing the most advanced and capable Helmet Mounted Display System (HMDS) for the F-35. Utilizing extensive design experience gained on successful production Helmet Mounted Displays (HMD), the F-35 HMDS will replace the traditional Head-Up-Display (HUD) while offering true sensor fusion. The F-35 need not be physically pointing at its target for weapons to be successful. This is possible because of sensors that can track and target a nearby aircraft from any orientation, provide the information to the pilot through his helmet (and therefore visible no matter which way they are looking, as it will be like seeing “across” the plane even if they look at the floor of the cockpit), and provide the seeker-head of a missile with sufficient information. Recent missile types provide a much greater ability to pursue a target regardless of the launch orientation, called "High Off-Boresight" capability, although the speed and direction in which the munition is launched affect the effective range of the weapon. Sensors use combined radio frequency and infra red (SAIRST) to continually track nearby aircraft while the pilot's helmet-mounted display system (HMDS) displays and selects targets. The helmet system replaces the display suite-mounted head-up display used in earlier fighters.

The F-35's systems provide the edge in the "observe, orient, decide, and act" OODA loop; stealth and advanced sensors aid in observation (while being difficult to observe), automated target tracking helps in orientation, sensor fusion simplifies decision making, and the aircraft's controls allow action against targets without having to look away from them.

An interesting factor is that the new BAE Striker helmet destined to use by Typhoon’s pilots on the Eurofighter, seems to offer the very same kind of performances. It makes me wonder if it wouldn’t be feasible for the UK to employ an updated Striker helmet on its own F35Cs to achieve economies of scale and commonality. Indeed, BAE has a chance of becoming the lead supplier of the F35 helmet technology, according to recent reports:

Lockheed Martin, prime contractor for the F-35 Joint Strike Fighter, has begun looking for an alternative helmet system for the stealthy aircraft, as problems with the current Vision Systems International helmet continue to plague the program.

Lockheed issued a March 1 draft specification for proposals on an alternate helmet-mounted display system that makes use of commercial, off-the-shelf night-vision goggles, according to John Kent, a Lockheed spokesman. A final request for proposals is expected by the end of the month, and a selection will be made by the end of June. Candidates include BAE Systems, Gentex and VSI, Kent says.

Continuing problems on the VSI helmet-mounted display system include jitter in displaying data on the visor and problems with the night-vision capability. VSI is a Rockwell Collins/Elbit joint venture.

Lacking a conventional HUD, the F35 is being damaged substantially by the un-performing helmet, which is also slowing down the beginning of US Air Force training on Eglin air base. It could be a serious advantage for the UK if the Striker helmet was chosen for use in the F35.

The cockpit of the F35 features a large eight-inch by 20-inch color display, providing tactical information as well as aircraft system data. A next-generation voice-command system allows the pilot to manage systems without manual input. Tasks such as changing radio channels are accomplished simply by speaking a command. The pilot also has the option to manipulate the displays by touching the screen or by using a yoke-mounted cursor. F-16 pilots, themselves accustomed to a superb pilot-vehicle interface, drop their jaws when they see the JSF's cockpit.

|

| An F35 cockpit mock-up shown to the public. |

It is completely night-vision capable. It offers exceptional lookdown angle over the canopy rail and an excellent field of view over the aircraft's nose. The F-35 provides its pilot with unsurpassed situational awareness, positive target identification and precision strike under any weather condition. Mission systems integration and outstanding over-the-nose visibility features are designed to dramatically enhance pilot performance. Rockwell Collins's 8"x20" Multi-Function Display System (MFDS) will be the panoramic projection display for the F-35. MFDS employs leading edge technology in projection engine architecture, video, compression, illumination module controls and processing memory – all of which will make the MFDS the most advanced tactical display. One-gigabyte-per-second data interfaces will enable the MFDS to display six full motion images simultaneously. The adaptable layout will be easily reconfigurable for different missions or mission segments. Projection display technology will provide a high-luminance, high-contrast, and high-resolution picture with no viewing angle effect.

Continuous tailhook-to-nose-gear structure and catapult-compatible nose gear launch system are strengthened for catapult and arresting loads. Engineers are exploiting the relationship between designing and manufacturing to further reduce cost. The aircraft's wingbox, for example, carries through the fuselage and integrates the wing and fuselage into one piece. By eliminating the side-of-body joint between these traditionally independent components, the design reduces much of the structure, weight and assembly typically associated with this interface.

The F35C has a wingspan of 13,11 meters compared to 10,67 for the other two variants, but the wingtips are foldable, and give the F35C the same deck footprint of an F35B (if not even a slightly narrower one). The wing surface is greater by 36% (from 42,7 square meters to 58,3) and it also has a much greater internal fuel capacity of around 10.920 liters of JP-8 fuel, for 8890 kg, against 8390 for F35A and 6030 for the F35B. Overall, the F35C is expected to be slightly slower than the F35A (but probably faster than the F35B), with unofficial reports suggesting that the greater drag caused by the larger wing and control surfaces might cause a drop from the max speed of Mach 1.66 to around 1.58. Hardly a worrisome factor, but it goes to underline, once more, than in terms of kinetic performances, the F35 is certainly not a top scorer. The Combat Radius requested by the US Navy was 600 naval miles, and the F35C more than met the requirement, and is projected to have an effective combat radius of 732 naval miles, which is well over twice the range of the old F-18.

The F35 has a 0,91 thrust/weight ratio with inner load and 60% fuel, and even lower ratio in clean configuration with 100% of fuel. The plane uses the most powerful jet fighter engine ever, but it has only one and it is a quite heavy machine, and this take a toll on the air to air ambitious of the aircraft. F35 is, primarily, the joint STRIKE fighter. It is not a bomb truck, but it is not an air dominance fighter either. Its acceleration capability is also not brilliant: to pass from Mach 0,8 to Mach 1,2 at 30.000 feet the F35 reportedly needs 61 seconds, against the 35 employed by a “legacy” fighter such as the F16C. At Mach 1,5 and 30.000 feet, the max Sustained Turning Rate of the F35 is barely 50% of that offered by the Typhoon. The F35C, in fact, is limited to a factor of 7.5G against 9 of the Typhoon, F35A and against the 7G of the F35B. The F35 bases its performances in air to air combat, much more than the F22 Raptor itself does, on being able to detect the enemy and fire at it first, and it has its domain in BVR engagements. With its maneuvering limitations, it certainly is not a dogfighter, even if modern missiles, coupled with the sensors and avionics of the plane, will mitigate at least in part the disadvantage.

Normally, the F35C will be able to fly 3 sorties a day in surge conditions, and sustain a rhythm of 2 missions a day afterwards. Tests suggest that the plane might actually be able to surge 4 sorties for day (the result of simulations was 4.4 sorties per day).

The F35's challenges

The F35 Joint Strike Fighter is a plane affected by some of the most demanding requirements and most ambitious objectives ever conceived. The plane had to be stealth, have a Carrier, a STOVL and air force variant with 90% commonality between the three, had to be affordable, and had to replace a massive array of successful and very different airplanes.

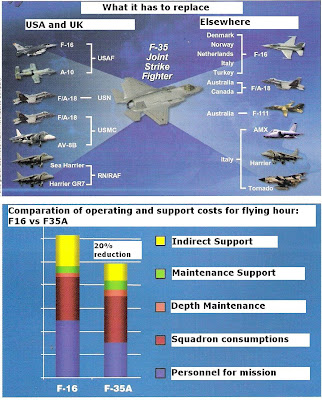

When we look at the Joint Strike Fighter, in fact, we see that it is supposed to replace planes such as F16, F18 (partially), A10 (again, partially, as the Warthog has in the years gained such a consideration thanks to its effectiveness that it is hard to see its retirement happening anytime soon), Harrier AV8B +. In the UK it was to replace the Harrier, but with the death of FOAS and the first operational UCAV expected not before 2030 it is now going to replace Tornado GR4 as well. In Italy it is to replace the Tornado, the Harrier AV8B + and the AMX.

Not an easy task at all!

Ambitious targets have been set also in terms of training (no twin-seat variant, Operational Conversion to type expected to be done mainly via simulators) and maintenance. To give an idea of how challenging the requirements in this field are, we have to consider that the AESA radar aerial is reportedly sealed, and will not require maintenance at all during its life, as its many modules will allow for a "graceful degradation" that does not affect performances during service.

With the F35, it is expected that Scheduled Maintenance periods will vanish: the plan is that the plane will "tell" to the technicians when it needs support and repairs and what it needs, thanks to its advanced Prognostic and Health Management System.

The F35 is asked to deliver a 20% reduction in support and maintenance needs (particularly about support personnel) compared to the F16, which notoriously isn't a maintenance-hungry machine to start with.

The F35 is not ambitious only in terms of kinetic performances. An F35 will spend most of its flying life not exceeding Mach 1.2 and 3 G (that are the Combat Mach limits), and its top performance is a rather uninpressive Mach 1.6. Turning rate and Specific Excess Power are also far from impressive, since the engine it uses its very powerful, but it is a lone engine pushing a very heavy plane!

Its avionics are top class, and its range is also very good (and might improve, as in Israel the industry has already announced the design of a conformal fuel tank F35-compatible, to answer to the IDF requirement for the expansion of the range of their F35A) but the Joint Strike Fighter is not a real fighter. It is a Strike plane, with better AA capability than a Tornado.

Overall, this is probably not a bad thing: today, "Air Dominance Fighters" such as the F22, targeted almost exclusively to the dog fighting and air supremacy, make little to no sense, as the reality is that planes such as the Typhoon will spend most of their time chasing surface targets.

However, ambitions have a cost, and this leads us to the main defect of the F35: it failed at being affordable. The "40 million dollars" wonder plane will never be. Up to 100 millions more will have to be added to that very optimistic figure, if not even more.

Engine

There are two engines that the F35 can use:

Pratt & Whitney’s F135, which received a 4-year head start on development thanks to a $4.8 billion System Development and Demonstration (SDD) contract on Oct 26/01, has received well over $1 billion in additional funding plus-ups since, and that number is set to grow to a total of $7.5 billion in funding over the F-35’s development period. It is already powering F-35 test aircraft, and equipping initial F-35 production models. It is currently about 24 months behind the 2001 schedule, however, and current plans would put it over budget by a reported $2.4 – 3.4 billion.

The JSF dual engine program has always envisaged a leader-follower strategy for development. When Boeing’s X-32 and Lockheed Martin’s X-35 competed to become the Joint Strike Fighter, Pratt & Whitney’s F119 was deemed to be the only production engine suitable for use as a base for an engine to power both aircraft. As the winning F-35 fighter’s SDD phase began, both engine types were already receiving funding, but the F135 engine had started much earlier, had begun development from an in-production base engine, and had already flown on the demonstrator aircraft.

The F135 engine comes in “A” variant, fitted with LiftSystem for “B” variant, and in “CV” variant for the F35C. The CV variant delivers the same thrust of the A variant (11.800 kg dry, 18.150 with afterburner at take off), but is strengthened for operations at sea. The F136 will follow the same lines.

The General Electrics and Rolls Royce’s F136 alternate engine is at an earlier stage of development. Follow-on F136 development was launched in earnest by a $2.47 billion SDD contract in August 2005, after almost $600 million in pre-SDD funding. The first complete new-build F136 engine began testing early in 2009, and expects to see flight testing by 2011-2012. If all goes well, the first production F136s could be available in 2012.

The F136 program is currently 2-3 months behind the original 2005 schedule, and on budget, but that must be tempered by having less testing under their belt. Additional engine costs and rework are always a risk once stress testing begins in earnest, and Congress has created issues by not providing the full amount of budgeted funding during development.

F136 engine development is being led by GE Aviation in Evendale, OH near Cincinnati suburb; and by Rolls-Royce in Indianapolis, IN. GE Aviation is responsibility for 60% of the F136 program, developing the core compressor, coupled high-pressure/low-pressure turbine system components, controls and accessories, and the augmentor. Rolls-Royce is responsible for 40% including the front fan, combustor, stages 2 and 3 of the low-pressure turbine, and gearboxes. International participant countries are also contributing to the F136 through involvement in engine development and component manufacturing.

On 20 March 2008, the F136 successfully completed a high-altitude afterburner testing program at the US Air Force Arnold Engineering Development Center in Tennessee, including common exhaust hardware for the F-35 Lightning II aircraft. All test objectives were reached as planned using an engine configured with Conventional Takeoff and Landing (CTOL) and Short Takeoff Vertical Landing (STOVL) common exhaust systems. The engine configuration included a production-size fan and functional augmenter allowing several run periods to full afterburner operation. The GE Rolls-Royce Fighter Engine Team successfully completed Short Take Off, Vertical Landing (STOVL) testing on an F136 engine at the GE testing facility at Peebles, Ohio on 16 July 2008.

The first complete new-build F136 engine began testing 30 January 2009, under the System Development and Demonstration (SDD) contract with the US Government Joint Program Office for the F-35 Joint Strike Fighter program. This marked the first complete engine assembled following US Government validation of the F136 design in 2008. The milestone was achieved one month ahead of schedule.

Citing the Weapon Systems Acquisition Reform Act of 2009, the GE Rolls-Royce Fighter Engine Team submitted an unsolicited fixed-price offer for the F136 to the Pentagon on 28 September 2009. The fixed-price approach would cover initial F136 engine production, beginning with the F136 second production lot. According to the GE Rolls-Royce Fighter Engine Team, the proposal would shift significant cost risk from taxpayers to the Fighter Engine Team until head-to-head competition begins between the F136 and the Pratt & Whitney F135 engine in 2013.

On the other hand, the USA’s fiscal crunch, and Congressional appropriations that have not matched promised program budgets, have created a more immediate set of pressures. The Pentagon has been trying to kill the F136 since 2006, but its premises have been found to be flawed or missing, and key analysts like Congress’ GAO auditors have consistently expressed support for the program. The question has now become whether the engine can survive politically, in order to become a viable competitive alternative for customers like Britain, the US Navy, et. al.

Rolls Royce’s LiftSystem fan for the F-35B STOVL will be common to both the F135 and the F136 engines, assuming that both the F-35B fighter and the F136 engine survive long enough to create a choice.

The Pentagon’s argument for canceling the F136 boils down to 2 main pillars. One is that the F135’s derivation from the F-22A Raptor’s F119 engine reduces its development risks (note that this assessment cheerfully ignores that the programme is already well over budget and at least 2 years late). The second contention is that The F135 is working well, which means any funds given to the F136 subtract from the total number of fighters in the F-35 program.

The Lockheed F-16, which currently flies with either P&W’s F100 or GE’s F110 engines, is an illustrative example of how a dual-source engine program can work. In program terms the F110 was introduced even later, fully 4 years after F-16s with P&W’s F100 began front-line operations in USAF units. Nevertheless, the strategy was a success. It created more competition, sustained the American industrial base by leveraging a popular fighter program in 2 ways, and led to a raft of technology improvements, from higher thrust engines to maintenance improvements. With 2 competitors available for American and foreign buys, each knows that complacency would lead to rapid replacement as the F-16’s engine of choice. Although the P&W F100 was the F-16’s original engine, and is still chosen by some foreign customers, GE’s F110 currently powers over 80% of USAF F-16 fleet.

Competition is even bleeding into the F-15 program. F-15s almost all carry variants of the F100, though some of Saudi Arabia’s F-15S and Korea’s F-15Ks, and all of Singapore’s F-15SGs, are breaking that mold by selecting GE’s F110.

Given the positive savings (estimated by GAO in 21%), maintenance and performance results from dual-sourcing the P&W F100 and GE F110 engines for the global F-16 and F-15 fleets, and the appeal of district jobs, the Pentagon has had an uphill battle on its hands in Congress trying to kill the F136.

One consequence of a single-engine program would be a major win for Pratt & Whitney, as it would be the engine supplier for the backbone of the US tactical fighter fleet and a potential export star. They would also inherit a very lucrative aftermarket of spare parts and support lasting until 2050 at least, and possibly beyond. Back on Feb 5/07, Senate Armed Services Committee chair Sen. John Warner (R-VA) grilled Defense Secretary Robert Gates and Pentagon Comptroller Tina Jonas over concerned that eliminating the F136 would be the equivalent of handing Pratt & Whitney sole engine development right:

“If we have but a single engine, then we’re in effect giving a sole-source contract to one contractor, which could amount to $100 billion…. I’ve calculated that out. It’s extraordinary.”

General Electrics, as a consequence, would remain largely cut out of the future market for fighter jet engines, and it might well be the end of its activity in the field.

In 2009, House Armed Service Air-Land Subcommittee chair Neil Abercrombie [D-HI] added the fleet reliability issue, stating that it simply was not prudent to have 80-90% of the USAF, Navy and Marine Corps’ fighter fleet dependent on one engine type, from one manufacturer, which can ground all of those fleets if mechanical flaws or difficulties surface.

Then there are the potential consequences for the JSF program as a whole. Britain has invested $2 billion in the F-35 as the only other Tier One partner, and the participation of Rolls Royce with GE in the aircraft’s F136 engine is an important industrial spinoff. In 2005, during one of the (many) Pentagon’s attempts to kill the F136 funding, the UK position was very strong: if the F136 engine was killed off, Washington would have seen the UK pulling out of the programme. The Dutch are also involved in F136 production, even as that Tier 2 partner considers alternative platforms like the JAS-39NG. Nedtech and DutchAero (formerly Philips Aerospace) have contracts with Rolls Royce for F136 backup motors and blisks, while Stork-Rheinmetall has testing contracts, and is leveraging its strong expertise in fan blades.

For all these reasons and more, the F136 has enjoyed bipartisan support from Armed Services committee members and the US Congress’ Government Accountability Office’s auditors have consistently supported the long term financial and operational benefits of a dual-engines program. In 2007, they estimated that sole-source lifecycle cost for the entire F-35 engine program at $53.4 billion, while the alternate engine program would require another $3.6 – $4.5 billion. They believe that actual experience from past engine competitions suggests that it is reasonable to assume savings of at least that much, while improving contractor and engine performance, and acting as a hedge against fleet-wide risk.

|

| F136 engine - partial cutaway |

All this support has helped the F136 surviving (so far) every attempt of killing it, from 2006 onwards, as in every yearly planning round the USAF has proposed cutting funding for the second engine in order to use the money on something else. However, 2011 saw the Alternate Engine programme badly hit:

“The Department of Defense (DoD) today (March 24 2011) issued a stop work order in connection with the Joint Strike Fighter extra engine program…. The House of Representatives has recently expressed its own opposition to the extra engine in its passage of H.R. 1 including the adoption of the Rooney Amendment which removed all fiscal 2011 funding for this program. In addition, funding for the extra engine was not authorized in the National Defense Authorization Act for fiscal 2011, enacted in January. In light of these recent events, Congressional prerogatives, and the administration’s view of the program, we have concluded that a stop work order is now the correct course. The stop work order will remain in place pending final resolution of the program’s future, for a period not to exceed 90 days, unless extended by agreement of the government and the contractor.”

The bit about 2011 continuing resolutions is technically true, insofar as no specific funding directives are offered at all for any part of the F-35 program. The decision pulls $460 million in funding from the program, and House Armed Services Committee chair Buck McKeon [R-CA-24] said that:

“The views of the president and Secretary Gates are well known on this topic [they want the F136 funding cancelled], but those opinions – however strong – are not the law. The Joint Strike Fighter F136 engine program is funded under the current continuing resolution. The secretary should follow current law and not pre-empt the congressional deliberation process by yanking funding after a single amendment vote…. canceling the engine competition and awarding a sole-source, never-competed contract constitutes the largest earmark in the history of the Department of Defense…. The Department’s decision is especially troubling when you consider their preferred engine has experienced development delays and a cost to complete increase of 445 percent over the last three years.”

Sen. John Kerry [D-MA] expressed similar concerns about the process, but restoring funding in the Senate, which struck it from the budget in 2010, and then persuading the House to go along in reconciliation, will be difficult. The Senate didn’t include the engine in its bill either, but senators voted down both versions, leaving the program in limbo. GE and Rolls Royce say they will now self-fund F136 development through the 90-day period, while continuing to make their case for the original dual-engine program. However GE is limited to design work only, as the stop-work prevents their use of the existing hardware, and in fact on 12 April 2011, GE cut its team of 1000 workers on this project down to 100, who will work on the F136 and engine technologies for "future combat aircraft". This comes despite the F136 having, in early 2010, reached full afterburn thrust during testing of the first production standard engine, which builds over 800 hours worth of testing.

The competing JSF engines from GE/Rolls-Royce and P&W are fully interchangeable. Simply put, you can pull out the engine from the JSF aircraft and quickly replace it with the engine from the competing supplier. Because the two engines have common specifications and interfaces with JSF, the pilot won't know which engine is powering the aircraft. The F136 is however a newly developed system, differently from F135 which is a redesigned F22 turbofan. The F136 has been designed specifically for the F35, and it was resized in 2005 to reflect growing demands of power of the F-35 aircraft. In fact, the F136 can grow in thrust by 5 percent without an engine redesign. The F136 has a clear thrust advantage: thrust has been reported at 19.050 kg with afterburner at take off, against the 18.150 kg of the F135 in equal conditions.

It is to be seen if the F136 will continue to live, or if this hundredth attempt of cancelling it will be successful. For now, the UK seems to be making a lot less noise about the matter, despite the damage that Rolls Royce would take from this decision, on top of the UK’s very own shift from F35B (which would have used RR’s Lift Fan system) to F35C and on top of the “two years probation time” the F35B has been put in. An apocalyptic scenario (not likely, but possible) might see Rolls Royce left without a part in the F35 programme, with the B variant and the F136 engine both killed. The damage to british industry would be massive.

It is to be expected that, if the F136 survives the political war and keeps faith to at least a part of its ambitious promises, it will have excellent hopes on the international and even US market. It offers clear advantages, and because of its high british content it would likely be mandated to power the UK’s share of F35s.

Another interesting factor and potentially huge issue for the F-35’s naval variants was raised in the article from NavyTimes, available at http://www.navytimes.com/news/2010/11/navy-jsf-engine-too-big-112910w/. The F135 engine and its packing are too large and too heavy for carrier aerial delivery platforms, and even too heavy for ship-to-ship replenishment stations. This will make sustained operations very difficult, as on-board space for spares is limited:

”...the F-35C’s Pratt & Whitney F135 engine, contained in its Engine Shipping System, is too large for the cargo door on a standard carrier onboard delivery plane and for the V-22 tilt-rotor aircraft, the program office acknowledged in a response to a follow-on query from Navy Times. The engine can be broken down into five component parts, but just its power module and packaging alone won’t fit into the [C-2 Greyhound] COD or the V-22. The JSF Program Office says the V-22 Osprey, like the MH-53E helicopter, can externally carry the F135 engine module, the heaviest of the five components, at least 288 miles “in good weather.” One outside analyst, Jan van Tol of the Center for Strategic and Budgetary Assessments, wondered how the Osprey, in hover mode, could safely lower the module to the flight deck or pick up an out-of-service engine in higher sea states…. Moreover, the Navy has no fleet V-22s and has no plans to acquire them.

The 9,400-pound engine module and transport container also cannot not be transferred from a supply ship to a carrier during underway replenishments [UNREPs] – when two ships are sailing side-by-side and connected by supply lines – because, [Capt. Chris Kennedy of the JSF Program Office] said, “It’s too heavy for the unrep station [on Nimitz class carriers].”

No word on whether the F136 has similar problems but it is more than likely. Note that Rolls Royce, however, has developed a new Replenishment At Sea ring system capable to deliver over 5 tons of weight between ships under way at sea, contrary to the roughly two tons available today. The new system has already been acquired with a 25 million contract by the Royal Navy, for now only to build a training facility ashore at HMS Raleigh base, but the new RAS system is undoubtedly going to be part of the kit fitted to the next RFA ships acquired through MARS. The UK seems to have the solution ready. VERTREPing a F35 engine on a carrier, however, remains a problem: for that weight, it take no less than a Merlin, if not a Chinook!

More details available in the Article.

Rolls Royce Lift System

Although the UK has now officially stepped away from the STOVL variant of the F35, british industry, thanks to Rolls Royce, continue to be the very heart of the ambitious F35B. I believe it is of great interest to take a closer look at the brilliant technology behind the F35B’s magic to see what british industry is capable of. And also, admittedly, to make it clearer that it is highly unlikely that the F35B will ever keep the promises made by the ones who said that a STOVL aircraft would require less mainteinance, spares and expenses than the C variant. The sheer complexity of the Lift System, and its countless, fatigue-exposed components make it evident that such an assumption can only be a fantasy.

|

| Rolls Royce LiftSystem concept art showing the various components. These are compatible with both F135 and F136 engines. |

The Rolls Royce LiftSystem is compatible with both F135 and F136 engines. It comprises:

- The Turbofan jet engine

- The LiftFan, a 50-inch two-stage counter rotating fan capable of generating more than 20,000lbs of cold thrust, is driven from a conventional gas turbine and produces the forward vertical lift.

- The 3BSM is a swivelling jet pipe capable of redirecting the main engine thrust downward to provide the aft vertical lift. It can rotate through 95 degrees in 2.5 seconds and passes 18,000lbf of thrust. Note that, as visible from the drawing, this component is not the final nozzle with afterburner, which is common and not an unique part of the STOVL system.

- Aircraft roll control and lateral stability is achieved using the Roll Posts mounted in the wings of the aircraft, which provide a further 1,950lbf thrust each.

In STOVL mode, doors open above and below the lift fan, a clutch engages to drive the two-stage contra-rotating fan from the engine and the rear nozzle pivots downward to deflect engine thrust. Flight control on vertical-lift mode is provided by vanes in a variable-area box nozzle beneath the lift fan, the roll ducts in the wing and the three-bearing swivelling nozzle. Deployment and stowing of the lift system is automatic. The shaft transmission is self-evidently a component exposed to major stress, and the complex system of doors and air intakes of the STOVL system are, in themselves, another area that will probably be mainteinance intensive. Problems (of minor entity) have already been encountered with the opening and closing of these doors in flight.

The LiftSystem-configured F136 delivers combined thrust in the order of “43.000 pounds” (190 Kilo Newton) and could be brought to 45.000 pounds. Although F135 has promised to bring its own thrust to 43.000 pounds as well, in tests the F135 only generated 41.000 pounds.

Experts agree that, as it is, the F136 offers superior performances and has more growth margin thanks to its bigger core. A staggering 56.000 pounds of future thrust after upgrades has been apparently suggested.

Weapons

The F35 has 6 underwing pylons, which can be used when stealthness is not required. The two external pylons are cleared for 300 to 350 pounds, and will be used for AA missiles. For the UK, these will come from the start integrated with ASRAAM thanks to current contracts signed with LM. The two middle underwing stations will be cleared for AA and AG weaponry up to 2500 pounds of weight, limited to just 1000 for the F35B variant.

It is unclear if the integration contract for Paveway IV for the UK includes external pylons or if it is limited to the inner weapon bays. Integration of weaponry, anyway, will be done in phases, as with all airplanes. The inner underwing pylons, capable of 5000 pounds each, will be used by UK F35C for Storm Shadow missiles. The integration of Storm Shadow was to be done from the start, but it is understood that in 2005 the UK delayed this measure to save money. (Typical labour fudging, already seen with other programmes, up to CVF itself…)

|

| A graphic of the pylons and of their capacity in pounds. F35A and F35C have the same capabilities, the F35B has reduced ones because of weight problems. |

It is unclear if the integration contract for Paveway IV for the UK includes external pylons or if it is limited to the inner weapon bays. Integration of weaponry, anyway, will be done in phases, as with all airplanes. The inner underwing pylons, capable of 5000 pounds each, will be used by UK F35C for Storm Shadow missiles. The integration of Storm Shadow was to be done from the start, but it is understood that in 2005 the UK delayed this measure to save money. (Typical labour fudging, already seen with other programmes, up to CVF itself…)

|

| Loadout graphic of the F35 pylons. Essentially, F35A and F35C can do the exact same things. F35B has reduced load capability and size constraints in the weapon bays. |

The two weapon bays include two pylons each, two on the doors for AA missiles, and 2 pylons for both AA and AG loads. The F35C can carry up to 4 AMRAAM internally (the RAF did not show great enthusiasm for the idea of fitting Meteor to JCA in the past years. Being evil as I am, I suspect that this is because they did not want to give the Fleet Air Arm such capabilities. However, now that there will be no FOAS and the JCA is the only fighter the RAF will get other than Typhoon, a Meteor requirement will undoubtedly be issued in due time), but a likely interim stealth fighter configuration for the RAF is 2 AMRAAMs on the AG pylons and 2 ASRAAMs on the AA pylons. As it stands, ASRAAM will not be cleared for carriage on the inner AG pylons: original plan was to ask for integration and have a possible load of 4 ASRAAM all carried internally, but this was later changed to 2 inside and 2 outside. It is admittedly difficult to imagine a situation in which you’d want to send out a F35 armed with 4 ASRAAMs carried internally, after all…

A centerline underfuselage pylon exists, cleared for 1000 pounds. This will be used on F35B and F35C to carry a missionized gunpod. Only the F35A could fit the gun internally, as it was discovered during design and development. The F35 will use a purposefully-designed version of the GAU-12 Equalizer gun used on AV8B Harriers. The same gun, ironically, redesigned by ADEN, was to equip the UK Harrier GR9, but as we know it never worked.

|

| F35 fitted with ventral gunpod and external stores |

The F35 variant is named GAU-22A, and maintains the caliber 25 x 237 mm NATO, but drops one barrel as a weight saving measure, going from 5 to 4. It gains an additional 1.4 milliradians radius accuracy in the process, according to tests. Firing rate goes down to 3300 rounds per minute, and the gunpod will include 225 rounds. The F35A will have 182.

|

| General Dynamics released this image of the gunpod being prepared for use on F35B and C |

F35 Specifications | |||||||||||||||||||||||||||||||||||||||||||||||||

F35C has a carrier approach landing speed of 145 knots. F35B has a flat deck STOL take off run of 751 feet (against requirement of 550) F35B has a Sky Jump take off run of 561 feet (against requirement of 450) F35B has a vertical bring-back payload of 3442 lbs against a requirement of over 5000. JCA Budget In May 2001 the following estimated procurement costs for JSF were given by the MOD:

Peak expenditure was considered likely to occur in 2013-14 and 2014-15. Costs have increased substantially since 2001. 6000 million pounds would now (possibly) buy the UK between 65 (worst-case (?) estimate, with F35C cost of 91 million pounds apiece) and 85 airplanes (at MOD cost estimate of 70 million pounds per plane). Effective production budget allocated, however, is now unknown, and unlikely to be decided before the next SDR in 2015. It was revealed in 2005 that the MOD had effectively cancelled much of the "expenditure on national requirements". Some £368 million was 'saved' by the cancellation or deferment of upgrades for UK weapons such as Brimstone and Storm Shadow. Currently, there’s no funding provided to integrate Meteor onto the F35, and Brimstone and Storm Shadow integrations have both been delayed in time. The only UK weapons that will be integrated from the start on the Lighting II are: Paveway IV (It is unclear if the bomb will be cleared only for internal carriage or for external as well) ASRAAM (2 internal, 2 external. The original requirement was for 4 internally, but this was later changed.) | |||||||||||||||||||||||||||||||||||||||||||||||||

| UPDATES | |||||||||||||||||||||||||||||||||||||||||||||||||

| 25 April 2011 - The U.S. Defense Department has formally terminated the General Electric/Rolls-Royce F136 alternative engine for the tri-service Joint Strike Fighter (JSF). GE and RR, along with Congress, were notified of the decision April 25. | |||||||||||||||||||||||||||||||||||||||||||||||||

General Electric spokesman Rick Kennedy said in a written statement that the company was disappointed but would comply with the termination notice. However, the company is not backing down from continuing the fight to save the engine. "[General Electric] and Rolls-Royce will work closely with our Congressional supporters during the 2012 budget process in pursuit of incorporating the engine into the program, and preserving competition," Kennedy said, echoing earlier comments by General Electric CEO and chairman Jeffrey Immelt. In a letter to GE Aviation employees, Immelt vowed to continue to fight to save the engine program. "I can assure you we are not giving up. We will fight to bring competition to the 2012 budget debate," he said. Immelt said that the government would forgo billions in long-term savings by canceling the F136, which he said has completed 80 percent of its developmental phase. "We will keep the core technical team together as we continue the fight, and reassign the other highly skilled employees of the F136 team to other Aviation programs," Immelt said. | |||||||||||||||||||||||||||||||||||||||||||||||||

| Time for the UK as main partner to remind the US of their direct interest in the F136, or see british investment in the JSF further wasted and deprived of the long-term industrial benefits that had been promised. May 5, 2011 - The GE/RR team announces that they will self-fund the F136 through FY 2011 and 2012, completing the remaining 20% of development. In return, they will retain the hardware, assemblies and testing capacity funded by the government. That would keep the alternative engine “viable” for both the F-35 and for a future U.S. Air Force long-range bomber, which gets initial funding in FY 2012, and is seen as the next "big thing" to pursue for all aeronautics industries in the states. According to a September 2009 cable from the U.S. Embassy in the Netherlands, published by Wikileaks, “prospects for winning continued Dutch support for the JSF are dim without continuation of the F136 program.” What about the UK, which is EVEN more involved in the F136 via Rolls Royce...? The MOD is still suffering from the backlash of the switch from B to C and afraid to remind Washington of the interests of the United Kingdom's industry...? May 11, 2011 - Flight tests continue, and Lockheed has released details of the overall flight test activity since March 31, and cumulative totals for 2011 test flights:

Meanwhile the US Air Force accepted into its fleet the first of a planned 1,763 production-model F-35 Lightning II stealth fighters when aircraft AF-7 arrived at Edwards May 6, to begin its flight test program. It is a F35A. Not everything is happy and cheerful, though: flying tests are apparently suggesting that the F35A might only have a range unrefuelled of 584 naval miles, against a requirement of 590 and projections that gave it at 605. The range calculation has been redone on B and C variants as well: now the B-model has a radius of 469 nautical miles and a requirement of 450; the C-model, 615 and 600. In 2004, the situation had been far different, with the B variant expected to do only 442 miles. Successive weight-reductions have changed that, so that even the new 469 figure for the B variant is actually a (rare) triumph. The C variant had been expected to be capable of 732 miles back then: evidently the additional fuel capacity allowed by the larger wings was overestimated. The drop in range is due to F-35's propulsion and avionics running at higher temperatures than expected. To compensate, more bleed air from the Pratt & Whitney F135 engine is used for cooling, but this reduced propulsion efficiency and shortened range by 19.3km, according to sources familiar with the design issues. Another 16.1km of range was lost by new estimates about the aircraft's actual fuel capacity. Finally, the weight and drag of the aircraft's electro-optical targeting system was factored into the F-35's performance calculations, further reducing range by 6.4km. As a result, the programme office is considering “realistic aircraft modifications to add fuel capacity” in an effort to meet the requirement, according to the SAR report. One simple change under review is a software tweak that would maximise the amount of fuel taken onboard during in-flight refuelling. Another relatively simple fix is to raise shut-off valves higher inside the fuel tank to create slightly more capacity, a source said. A more complex solution also being considered is to install new fuel tanks in a small number of hollow spaces within the aircraft's structure. But programme officials are also debating whether to change how the range of the F-35A is calculated, the source said. The equation does not include a buffer margin of 5% of fuel capacity, which is intended to be preserved through the end of the flight test period in 2016. Eliminating the buffer margin adds another 72.4km to the aircraft's combat radius, the source said. Not a big problem, in the end. Yet, it is not good material to supply the press with, with how controversial the programme already is. 24 May 2011 - two recent parliamentary answers disclose very significant data about the F35 JCA: Peter Luff (Parliamentary Under Secretary of State (Defence Equipment, Support and Technology), Defence; Mid Worcestershire, Conservative) To meet the Joint Combat Aircraft requirement we are collaboratively developing a Joint Strike Fighter (JSF) air system with the US and other international partners through the JSF Systems Development and Demonstration (SDD) phase. Peter Luff (Parliamentary Under Secretary of State (Defence Equipment, Support and Technology), Defence; Mid Worcestershire, Conservative) The Department has not made an estimate of the number of jobs that the joint strike fighter (JSF) programme will provide throughout its life. We do not have any information as to the number of jobs which may be created in other participant nations. However, in the production phase, British companies secured some 15% of the JSF industrial programme estimated at around £35 billion.It is significant that the industry (and the government, through tax revenues) get back so much (35 billions for industry) from 2097 million so far spent. Of course, the cost of ordering the planes still has to be factored in, but this remains a very noticeable return. Not something that people will say when they demonize the defence industry. 20 July 2011 - F35C Updates US Navy test pilot Cmdr. Eric “Magic” Buus brought F-35C test aircraft CF-3 into launch position on a test catapult July 19. The test demonstrated proper catapult hook up in preparation for the first launches at Lakehurst, N.J., scheduled for later this month. CF-3 is the designated carrier suitability test aircraft. This follows a week of testing for ensuring compatibility of the F35C with the various configurations of Jet Blast Deflectors used on the US Carriers. Together, they represent a major step forwards for the C's walk towards operations at sea. Meanwhile, the UK has offered to the US to make an equal exchange: the third test plane ordered by the UK, an F35B, would be given to the US Marines in exchange for a F35C. The Pentagon is reportedly supportive of the request, and has defined the swap as "mutually beneficial" and "cost neutral": they have, after all, more need of further F35Bs with which ironing out the problems of the type before the 2-years probation time is over than need for further F35C at the moment. The UK is going to pay for the fitting of UK-specific equipment on one of the F35C on the production line, and it will finance the changes to bring the B model in line with US Marines requirements. The approval of the swap is not yet formal as it will require minor modifications in the Pentagon's budget figures 2012. 27 July 2011 - The F35C has been successfully launched with a catapult for the first time. Prototype CF-3, the newest C test plane, has been launched at the U.S. Navy's aviation test facilities at Naval Air Station Lakehurst, N.J., Naval Air Systems Command (NAVAIR) said in a press release. It was flown by Navy test pilot Lt. Chris Tabert, the most junior test pilot yet to fly any variant of the F-35. The launch was made with a C13 Mod2 steam catapult, the model currently used on all US Carriers and on Charles de Gaulle. Further tests lie ahead at Lakehurst, including launching the aircraft at varying catapult power levels, testing degraded catapult configurations, and jet blast deflector testing. The F35 is also respecting its targets for Low Observability, but the problem now is to ensure that it can be mass produced without degradations in stealthness. Currently, F35 production is still "handcrafting", and often a completed plane needs rework to correct faults and defects and ensure the proper low observability is reached, but this will have to change. Meanwhile, efforts to lower the costs continue as the Pentagon and industry begin negotiating for the next production lot, the fifth batch of low-rate, initial production (LRIP) jets. DoD officials are currently evaluating Lockheed Martin and subcontractor proposals for that batch of aircraft, and an agreement should be reached by the end of the year. October 11, 2011 - The enduring problems with the integrated Helmet Mounted Display produced by Vision Systems International (VSI), a Joint Venture between Elbit Systems and Rockwell Collins (see article above for more detail) has ultimately pushed Lockheed Martin in a quest for a new HMD. BAE System has been selected for providing the new HMD from 2012 onwards. The new HMD incorporate the Q-Sight waveguide display (a monocular variant was acquired by the UK mod and issued to helicopter gunners on Lynx helicopters of the Navy, to provide them with situational awareness) and feature detachable Night Vision Goggles for night operations. The HMD will also incorporate an optical Head Tracking System for precise weapons delivery and carrier and land-based operations. The issues encountered by VSI the integration of Distributed Aperture System (DAS), multiple infrared cameras positioned around the aircraft providing hemispherical view of the aircraft surrounding. The integration of the DAS infrared signals onto the HMD visor was supposed to provide the pilot with night vision derived from the DAS, but this solution caused problems with visual acuity and night-vision sensitivity. Lockheed Martin, the prime contractor opted to reduce the risk by opting for a near term solution based on a conventional off the shelf technology and the use of NVG when required. BAE system will now provide this interim solution. At the same time, according to Lockheed martin, the development of the original VSI HMDS will continue under a new contract recently issued. To further mitigate risk, the alternative HMDS is not required to have binocular symbology or to display image data from the F-35’s DAS. These features will be added if the BAE helmet eventually becomes the baseline system, Lockheed Martin said. This is an important news for BAE, which can work on an offer for long term selection, helped by its experience with the complex Striker helmet used by Typhoon pilots. It represents a huge opportunity for gaining a long term, massive market which would secure jobs and profits for years into the future. | |||||||||||||||||||||||||||||||||||||||||||||||||